Behind every Amazon delivery is a complex system that keeps millions of packages moving globally. With 9 billion items delivered in 2024 alone, Amazon’s supply chain has become a crucial selling point for marketplace sellers, especially in peak season.

For eCommerce sellers, understanding how Amazon handles everything from warehousing to delivery is crucial to building a profitable brand. In this guide, we’ll give you a comprehensive overview of the key elements of Amazon’s supply chain—and how you can leverage them to grow your business.

Key Takeaways: What to Know About Amazon’s Supply Chain

- Amazon’s supply chain combines advanced technology with efficient logistics networks to fulfill orders quickly

- From robotics to RFID tracking, Amazon’s innovations create opportunities for cost savings and better customer experience

- Amazon’s private labeling strategies help control product quality and availability

- Understanding Amazon’s supply chain options gives sellers a strategic advantage

- Third-party services like Trellis can help maximize your success on Amazon

Amazon Supply Chain Stages (2025)

Typical lead times vary by product and supplier:

Sourcing: 30–90 days

Production: 30–60 days

Shipping: 15–45 days

FBA Receiving: 3–7 days

That means total lead time can range from 80 to 200 days, depending on location and complexity. Planning ahead is key to avoiding costly stockouts.

Stay Ahead: Use the Product Sales Estimator Tool to evaluate your product and your strategy in context, ensuring consistent in-stock performance.

Sellers maintaining a 90+ day inventory buffer achieved a 94% in-stock rate, compared to 73% for those with only a 30-day buffer.

What Is Amazon’s Supply Chain Model?

Amazon’s supply chain model encompasses the entire process of sourcing, storing, and delivering products to customers. Technology and innovation are at its core—cloud computing, robotics, machine learning, and AI—seeking to improve efficiency and reduce costs.

The company has built hundreds of fulfillment centers strategically positioned worldwide, bringing products closer to customers and enabling faster shipping. Amazon Prime now has over 200 million members, further boosting efficiency.

But what exactly does the Amazon supply chain entail? Let’s take a closer look at each component.

Warehousing

Amazon’s fulfillment network includes a vast web of warehousing centers in strategic locations—one of the largest warehousing systems in the world.

These centers include:

- Sortable fulfillment centers: Pick, pack, and ship small items using robotics alongside human workers

- Non-sortable fulfillment centers: Handle bulky items like furniture and outdoor equipment

- Sortation centers: Sort and consolidate orders by final destination for faster delivery, including Sunday delivery

- Receive centers: Process large orders and distribute high-demand products to appropriate fulfillment centers

- Specialty buildings: Handle specific categories, including temperature controlled storage for perishables and pop-up fulfillment centers for seasonal demand

- Delivery stations: Prepare orders for last-mile delivery to customers

Increase RoAS on Amazon By 100%

See how our formula improves your advertising KPIs in 8-12 weeks in almost every category.

Delivery

Amazon relies on multiple carriers, including its own Amazon Logistics (AMZL), which handles about 46% of packages. They also partner with UPS, FedEx, and USPS for transportation from fulfillment centers to customers.

AMZL operates its own delivery fleet of vans, trucks, bicycles, and even drones. In select markets, Amazon’s drone delivery service Prime Air can deliver packages under 5 pounds in less than an hour, offering a new level of speed for eligible items.

Amazon Air, a fleet of over 70 cargo planes, supports the company’s commitment to one- or two-day delivery for Prime members. Amazon is currently prioritizing larger aircraft to increase capacity and efficiency in its air network.

Automatic Inventory Replenishment With Fulfillment by Amazon (FBA)

With FBA, sellers can store their products in Amazon’s fulfillment centers, and let Amazon handle the picking, packing, and shipping process. Sellers get the advantage of using Amazon’s machine learning algorithms to automatically replenish inventory based on forecasted demand.

Benefits of automatic inventory replenishment include:

- Faster deliver speeds with FBA

- Ability to fulfill off-Amazon orders through Multi-Channel Fulfillment (MCF)

- Optimized inventory placement for same-day or next-day delivery

Amazon’s MCF service allows sellers to use FBA inventory to fulfill customer orders from other channels, including their own websites, with Amazon’s competitive shipping rates and delivery speeds.

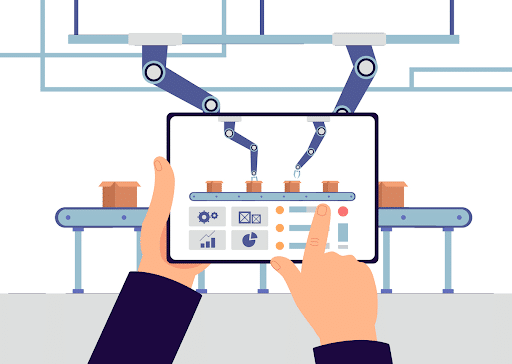

Robotics Technology

Amazon has invested heavily in automation for processes like picking, sorting, and packing. The company currently has more than 750,000 robots working alongside employees to streamline operations, reduce human error, and increase efficiency.

The different types of robots include:

- Sequoia: Stores and retrieves inventory

- Hercules: Transports pods of items to employees for processing

- Sparrow: Detects and sorts products into totes for packaging

- Titan: Transports large and bulky items

- Packaging Automation: Creates packages that are sized to fit to minimize waste

- Robin: Lifts and sorts outbound packages

- Cardinal: Loads packages into carts “in a Tetris-like manner”

- Proteus: Moves package carts to loading docks

For the record, we’re a little disappointed that the Packaging Automation bot didn’t get a cool name like the rest. (Between us, we’d call it Falcon.)

Artificial Intelligence Applications

Amazon is, of course, implementing advanced AI systems in its eCommerce supply chain. These systems analyze vast amounts of data to identify trends, spot potential issues, and make real-time adjustments for timely delivery.

Key AI applications include:

- Predictive route optimization: Maps optimal delivery paths accounting for traffic, weather, and road closures in real-time

- Vision-assisted package retrieval: Helps drivers quickly find the right packages at each delivery stop

- Package decision engine: Reduces waste by determining the minimum packaging needed for each order

- Automated damage detection: Identifies damaged items with accuracy three times better than human inspection

- Inventory intelligence: Forecasts demand patterns to prevent both stockouts and excess inventory

- Real-time supply chain visibility: Monitors entire product journey from manufacturer to customer doorstep

- Voice-directed warehouse operations: Guides workers through tasks with hands-free direction

These AI-powered systems create an increasingly autonomous supply chain that adapts to changes without human intervention, contributing to both efficiency and customer satisfaction.

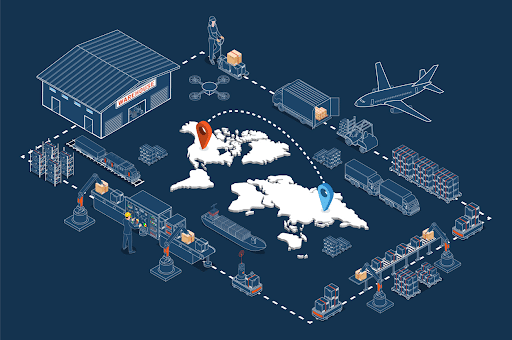

International Markets

Amazon’s global reach allows sellers to expand internationally regardless of physical location. Fast-growing markets include North America, Europe, Asia, and the Middle East.

Amazon Global Logistics (AGL) simplifies international shipping from mainland China and Hong Kong to FBA centers in the US, UK, and several European countries. The service includes:

- Origin pickup

- Cargo preparation and insurance

- Export documentation

- Ocean freight transportation

- Customs clearance

Sellers can book, track, and pay for shipments directly through Seller Central, choosing between full container load (FCL) and less-than-container load (LCL) options, as well as standard or expedited ocean freight.

Inventory Tracking Through RFID Technology

Amazon uses RFID technology throughout its supply chain for more accurate tracking and inventory management. While this technology does improve efficiency, successful implementation can be tricky—Amazon has recently scaled back its cashierless “Just Walk Out” technology in some stores after reports that humans were actually reviewing most of the purchases.

The takeaway for sellers is that Amazon continues to invest in tracking technologies that create efficiencies, but remains willing to adjust based on real-world performance.

Manufacturing

While Amazon doesn’t manufacture products directly, it’s expanding its private label strategy. Recently, Amazon launched Amazon Saver, a new private label brand offering everyday household items at competitive prices.

This addition to their private label collection allows Amazon to maintain quality control while also increasing profit margins through direct-to-consumer sales.

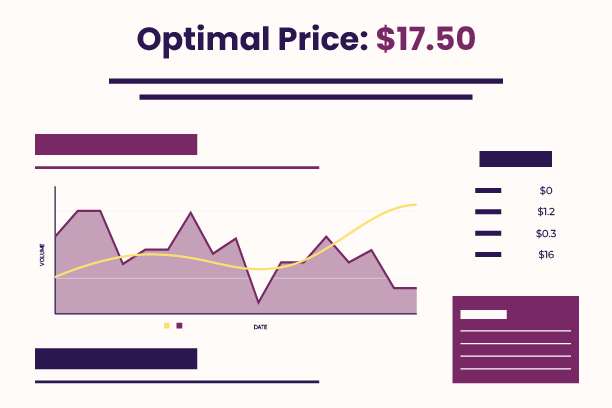

Pricing

Amazon’s pricing ecosystem creates both challenges and opportunities for sellers. Prime members expect competitive pricing and fast shipping—but they also drive higher conversion rates.

Amazon storage fees directly impact profitability, as long-term storage fees increase significantly for inventory held beyond 365 days. This creates pressure to maintain optimal inventory levels through accurate forecasting.

Advanced sellers implement dynamic pricing strategies that automatically adjust to market conditions, analyzing competitor behavior, inventory levels, and sales data to optimize prices in real-time.

Find Your Most Profitable Price

Enter your ASINs into our price calculator to analyze your BSR against historical price changes.

International markets

One of the most significant advantages of selling on Amazon is its global reach. The platform allows sellers to grow their business internationally, regardless of physical location. From North America to Europe, Asia, the Middle East, and beyond, Amazon has a vast network that provides an excellent opportunity for sellers to share their brand to millions of loyal customers.

Some of the key markets on Amazon include:

-

- North America: amazon.com, amazon.ca, and amazon.com.mx

-

- Europe: amazon.co.uk, amazon.de, amazon.fr, amazon.it, amazon.es, amazon.nl, amazon.se, amazon.pl, and amazon.com.tr

-

- Asia: amazon.co.jp, amazon.in, and amazon.sg

-

- Middle East: amazon.ae, amazon.sa, and amazon.eg

-

- Other: amazon.com.au and amazon.br

This global reach allows sellers to tap into new markets, reach a wider audience, and diversify their customer base while leveraging Amazon’s logistics network for timely and efficient delivery.

How is the Amazon supply chain so successful?

The success of Amazon’s supply chain management can be attributed to its efficient and highly integrated operations, innovative use of technology, strategic partnerships, and relentless focus on customer satisfaction.

With a vast network of warehouses, transportation services, fulfillment centers, and customer service functions all working together seamlessly, Amazon has created a well-oiled machine that delivers products to customers quickly.

The company’s investments in technology and automation have also played a significant role in streamlining operations and reducing costs, allowing for faster order processing and delivery times.

Moreover, Amazon’s strategic partnerships with third-party carriers, manufacturers, and suppliers have enabled the company to expand its reach globally while also providing a diverse range of products and offerings to customers.

But perhaps the most crucial factor in Amazon’s success is its unwavering dedication to customer satisfaction. The company’s commitment to fast, reliable delivery, excellent customer service, and competitive pricing has earned it a loyal base of customers and sellers alike.

How does Amazon manage logistics?

As one of the largest eCommerce platforms in the world, Amazon’s logistics operations are highly complex. Amazon has developed a sophisticated system to manage the entire supply chain process, from receiving products to delivering them to customers.

Receiving products

While half of the products sold on Amazon are from third-party sellers, the other half are fulfilled by Amazon’s facilities. When goods arrive at an Amazon fulfillment center, they are manually palletized or removed from trailers using a forklift. The shipments are then divided into those from an Amazon facility and those shipped through FBA.

Storing products

Unlike traditional warehouses that store items by type, Amazon’s fulfillment centers use a randomized storage method. Products are stored in yellow-tiered bins and tracked by computers for quick access. This method allows for efficient use of warehouse space and faster order processing. Holding also comes with fees, and Amazon charges based on the product size.

Storage fees

Amazon’s storage fees can vary depending on the type of products, size, and time of the year. Here is a range of storage fees for Amazon FBA 2023:

-

- Inventory storage fees: $0.56 – $3.63 per cubic foot

-

- Unplanned fees: $0.20 – $2.00, per single service, per unit

-

- Fulfillment fees: $3.22 – $179.28 + $0.83/lb above the first 90 lb

-

- Return processing fees: $2.12 – $75.08 + $0.25/lb above the first 90 lb

-

- Long-term storage fees: $1.50 – $6.90 per cubic foot

-

- Removal fees: $0.97 – $13.05 + $1.06/lb above 10 lb

-

- For small businesses looking to keep storage fees reasonable, having comprehensive marketing insights in place is crucial. At Trellis, we can help you with metrics and details related to pricing, advertising, and promotions to ensure your products flow in and out of Amazon warehouses with ease, eliminating unnecessary storage fees.

Picking orders

After placing an order, Amazon uses a combination of humans and robots to fulfill it. The process begins with sending the order to a picker who locates the product in the warehouse using an advanced barcode system. They then place it into a yellow tote, which is then transported by robots to a packing station.

Quality assurance

To ensure efficient operations, Amazon has a rigorous quality assurance process in place. This involves checking that the physical location of items matches the program database and monitoring the correct operation of robots. Any issues are quickly identified and addressed to maintain the smooth flow of operations.

Packing orders

Once the products are picked, they are sent to a packing station. Here, Amazon’s algorithms determine the appropriate box size for each item based on its dimensions and weight. The system also recommends the amount of tape required, reducing wasted materials and saving time for employees.

Items sold by third-party vendors are shipped in their original packaging whenever possible. However, Amazon works with vendors to reduce packaging and promote sustainability.

Shipping orders

After packing, the orders are sent to the shipping department and sorted based on the delivery method and destination. Amazon partners with major carriers like FedEx and UPS, allowing efficient and timely delivery.

Order returns

Amazon’s customer-centric approach extends to its returns policy. The company offers a generous 30-day return window for most products, with some exceptions. Sellers who use FBA are also subject to the same return policies as items fulfilled by Amazon. This allows customers to shop confidently, knowing that if they are unhappy with their purchase, they can easily return it using their Amazon RMA number.

FBA vs. FBM

Fulfillment by Amazon (FBA) and Fulfillment by Merchant (FBM) are two different options for Amazon sellers to manage their orders. Each has advantages and considerations for sellers to weigh before choosing the best option for their business.

Increase RoAS on Amazon By 100%

See how our formula improves your advertising KPIs in 8-12 weeks in almost every category.

What Is Supply Chain by Amazon?

Supply Chain by Amazon offers end-to-end supply chain services to move products from manufacturers to customers worldwide—including sales on and off Amazon. According to Amazon, this service increases sales by an average of 20% by streamlining operations and optimizing inventory.

The costs of the program vary by inventory weight and dimension, as well as seasonality. However, there are cost advantages: Sellers qualify for 25% lower storage fees and 15% less in transportation and processing costs associated with Amazon Warehouse and Distribution services.

Supply Chain by Amazon offers sellers three tiers:

- Standard: Ideal for businesses shipping 1-10 containers annually; basic shipping and storage services

- Premium: For businesses shipping 10-100 containers; improved rates and enhanced inventory management

- Enterprise: For high-volume sellers; priority handling and dedicated support

Freight and Logistics

Supply Chain by Amazon simplifies international product movement with automated customs clearance and streamlined shipping processes. Sellers can ship inventory directly from manufacturers to Amazon’s facilities, reducing transit time and handling points.

Warehousing and Distribution

The Amazon warehousing network becomes your distribution center, so your inventory is positioned close to customers for faster delivery. This allows you to store products for all sales channels in one place, reducing complexity and administrative overhead.

Fulfillment and Delivery

Amazon keeps the same delivery promise regardless of which channel generated the sale, creating consistency for your customers. Your inventory is consolidated as a single pool to fulfill orders from Amazon, your website, or other channels like FBA, MCF, and Buy with Prime.

Essentially, Amazon is now offering “supply chain as a service.” The company took the supply chain it’s been refining for decades and turned it into a new revenue stream—while helping sellers streamline their logistics and operations.

How Does Amazon Manage Logistics?

As one of the largest eCommerce platforms in the world, Amazon’s logistics operations are highly complex. Amazon has developed a sophisticated system to manage the entire supply chain process, from receiving products to delivering them to customers.

Receiving Products

About 60% of the products sold on Amazon come from third-party sellers. Amazon’s receiving process has gradually evolved to replace manual processes with automation. Today, most facilities employ robots to unload and process incoming inventory.

Storing Products

Unlike traditional warehouses that store items by type, Amazon’s fulfillment centers use a randomized storage method. Products are stored in tiered bins and tracked by computers for quick access. This method allows for efficient use of warehouse space and faster order processing. Amazon charges storage fees based on product size.

Storage Fees

Amazon’s storage fees depend on the type of products, size, and time of the year. Here are the ranges sellers can expect:

- Inventory storage fees: $0.87-$2.85 per cubic foot (Q1-3); $2.40-$4.75 per cubic foot (Q4)

- Long-term storage fees: $1.50 per cubic foot (items stored 271-365 days); $6.90 per cubic foot (365+ days)

- Fulfillment fees: $3.25 based on size

- Removal fees: $1.04-$15 per item based on size

- Return processing fees: $1.65-$150 per unit

Managing these fees requires careful inventory planning. Trellis’ Amazon Seller software helps sellers track pricing, advertising, and promotion metrics to optimize inventory flow and minimize unnecessary storage costs.

Picking Orders

Amazon uses both humans and robots to fulfill orders. New orders are sent to robot pickers, which locate product pods in the warehouse using an advanced barcode system. A human at the “pick station” checks for damage and places it into a yellow tote, which is then transported by robots to a packing station.

Quality Assurance

To ensure efficient operations, Amazon has a rigorous quality assurance process in place. This involves checking that the physical location of items matches the program database and monitoring the correct operation of robots. Any issues are quickly identified and addressed to maintain the smooth flow of operations.

Packing Orders

Amazon’s algorithms determine the optimal box size for each item based on dimensions and weight. The company has committed to sustainability, reducing packaging waste by 43% since 2015. When possible, third-party products ship in their original packaging.

Shipping Orders

After packing, the orders are sent to the shipping department and sorted based on the delivery method and destination. Amazon partners with major carriers like FedEx and UPS, allowing efficient and timely delivery.

Order Returns

Amazon’s 30-day return policy applies to most products with some exceptions. FBA sellers follow the same return processes as Amazon-fulfilled items. This allows customers to shop confidently, knowing that if they are unhappy with their purchase, they can easily return it using their Amazon RMA number.

FBA vs. FBM: How to Choose

Fulfillment by Amazon (FBA) and Fulfillment by Merchant (FBM) are two different options for Amazon sellers to manage their orders. Each has advantages and considerations for sellers to weigh—here’s a quick overview.

|

Feature |

Fulfillment by Amazon (FBA) |

Fulfillment by Merchant (FBM) |

|

Storage and fulfillment |

Amazon stores, packs, and ships |

Seller or 3PL handles logistics |

|

Buy Box advantage |

Yes |

Limited |

|

Prime eligibility |

Yes |

Only with Seller Fulfilled Prime |

|

Customer services |

Handled by Amazon |

Handled by seller |

|

Global fulfillment |

Yes |

Depends on seller capabilities |

|

Costs |

Storage, fulfillment, and referral fees |

Lower storage costs, higher shipping |

|

Control |

Limited packaging customization |

Full control over experience |

|

Best for |

High-volume, lightweight items |

Bulky items, unique packaging needs |

Fulfillment by Amazon (FBA)

FBA offloads logistics operations to Amazon’s established infrastructure, freeing up your resources to focus on product development and marketing. While providing significant advantages for search ranking and conversion rates, it requires careful inventory management to avoid escalating storage fees, particularly during Q4 when fees nearly double.

Fulfillment by Merchant (FBM)

FBM gives you complete control over your order fulfillment process, allowing for custom packaging, personalized inserts, and direct customer communication. This approach works particularly well for higher-margin products, oversized items, and businesses with established logistics capabilities or unique handling requirements.

The right choice depends on your business model, product type, and resources. Many successful sellers use a hybrid approach, using FBA for fast-moving items and FBM for others.

Amazon Supply Chain Management: 7 Best Practices for Sellers

Now that you’ve got all the details on Amazon’s supply chain strategy, how can you make the most of it for your own brand’s profitability? Here are seven strategies to consider.

1. Adjust pricing and advertising strategically

Take control of pricing and promotion for proactive inventory management on Amazon.

- Examine seasonality to identify when products need pricing adjustments based on demand cycles

- Set up automated rules to increase advertising spend on slow-moving inventory before it ages into higher storage fee tiers

- Use lightning deals and coupons for items approaching the 365-day storage threshold

The right pricing and promotion strategies can increase sell-through rates to help you avoid unnecessary storage fees.

2. Diversify suppliers

Building a strong supply chain starts with identifying and mitigating potential disruptions.

- Create a risk matrix ranking products by sales volume and profit margin, then focus your diversification efforts on the most impactful ASINs

- Develop relationships with suppliers in different geographies to protect against regional disruptions

- Negotiate better terms based on consistent ordering patterns rather than just volume commitments

A diversified supplier network can mean maintaining stock levels during disruptions while competitors struggle to balance the risk of stockouts and overstocks.

3. Use FBA and AGL when cost effective

Amazon’s fulfillment services are convenient, but it’s vital to do a cost analysis to determine whether using them is the right move for your long-term profitability.

- Compare total delivered costs including storage, fulfillment, and shipping when evaluating FBA vs. alternatives

- Consider seasonal fees, especially during Q4 when storage costs nearly double

- Factor in the value of Prime eligibility, Buy Box advantages, and reduced customer service burden

Many sellers use FBA for fast-moving items and alternatives for slow-moving or oversized products to keep things moving without exorbitant fees.

4. Stay compliant with Amazon’s rules

Amazon’s compliance requirements change regularly and non-compliance can result in penalties or account/product freezes.

- Schedule quarterly reviews of Amazon policy updates, which often align with seasonal shifts

- Subscribe to Amazon’s notification systems to receive immediate alerts about policy changes

Staying compliant also ensures your products remain eligible for premium placements and promotions like Deal of the Day.

5. Implement dynamic pricing

Dynamic pricing tools help you stay competitive while protecting your profit margins.

- Configure algorithms to account for both competitive positioning and inventory age

- Establish price floors based on profitability after all Amazon fees are considered

Brands using Trellis’ dynamic pricing tool saw a 40% increase in profit per session compared to those using static pricing strategies.

6. Understand your lead times

Accurate inventory planning requires a thorough understanding of your supply chain timeline.

- Document standard lead times for each product and supplier, including manufacturing, shipping, and fulfillment center processing

- Build in buffer time during peak seasons when delays are more common

By getting ahead of lead times, you can maintain optimal inventory levels without excessive stock (and storage costs).

7. Consider third-party logistics

A 3PL partner can complement your Amazon supply chain strategy and give you extra flexibility.

- Look for providers with direct integration to both your eCommerce platform and Amazon

- Choose partners based on proximity to both your customers and Amazon fulfillment centers

- Consider specialized handlers for unique products that aren’t well-suited for FBA

The right 3PL relationship creates a flexible inventory network that can adapt to changes and growth.

By understanding and optimizing your approach to Amazon’s supply chain, you’ll be better positioned to grow your business while controlling costs and delivering the experience customers expect.

Use Amazon’s Supply Chain to Build Sustainable Profitability

Understanding how the Amazon supply chain works is crucial for sellers looking to succeed on the platform. By tapping into Amazon’s resources and expertise, sellers can benefit from faster shipping times, cost savings, and more control over their operations.

Advertise smarter, automate sophisticated pricing strategies, and drive profitable growth for your business with Trellis’ powerful Amazon Seller platform. Our Amazon experts will show you how it works—book a demo today.

Frequently Asked Questions

Amazon invests heavily in its supply chain and logistics processes to ensure they are efficient and resilient. They have multiple fulfillment centers strategically located across the US and worldwide, reducing the risk of any disruptions. Amazon’s advanced technology and automation help them quickly identify and address any issues that may arise.

While both Amazon and Walmart have robust and efficient supply chains, each one approaches it differently. Amazon focuses on direct-to-consumer sales, with a vast network of fulfillment centers to provide fast delivery times to customers. On the other hand, Walmart relies more on its brick-and-mortar stores for sales but has been investing in online sales and improving its logistics processes.

Amazon’s success in mastering the supply chain can be attributed to its continuous investments in technology and automation. They have also built a robust network of fulfillment centers, negotiated lower shipping rates with carriers, and introduced innovative programs like FBA and Prime that benefit customers and sellers.

Additionally, their customer-centric approach ensures that they are constantly improving and adapting to meet the changing demands and expectations of consumers. Overall, Amazon’s relentless focus on improving its supply chain has been a critical factor in its dominance as an eCommerce giant.